Lot Traceability

Built for owner-led food manufacturers who need answers in seconds—not spreadsheets in a panic.

The problem with manual traceability

Manual traceability “works” — until something goes wrong.

Records live in different places.

Lots get copied wrong.

And finding the answer takes hours.

By the time you compile the trail, it’s already late.

That delay increases risk in recalls, audits, and retail relationships.

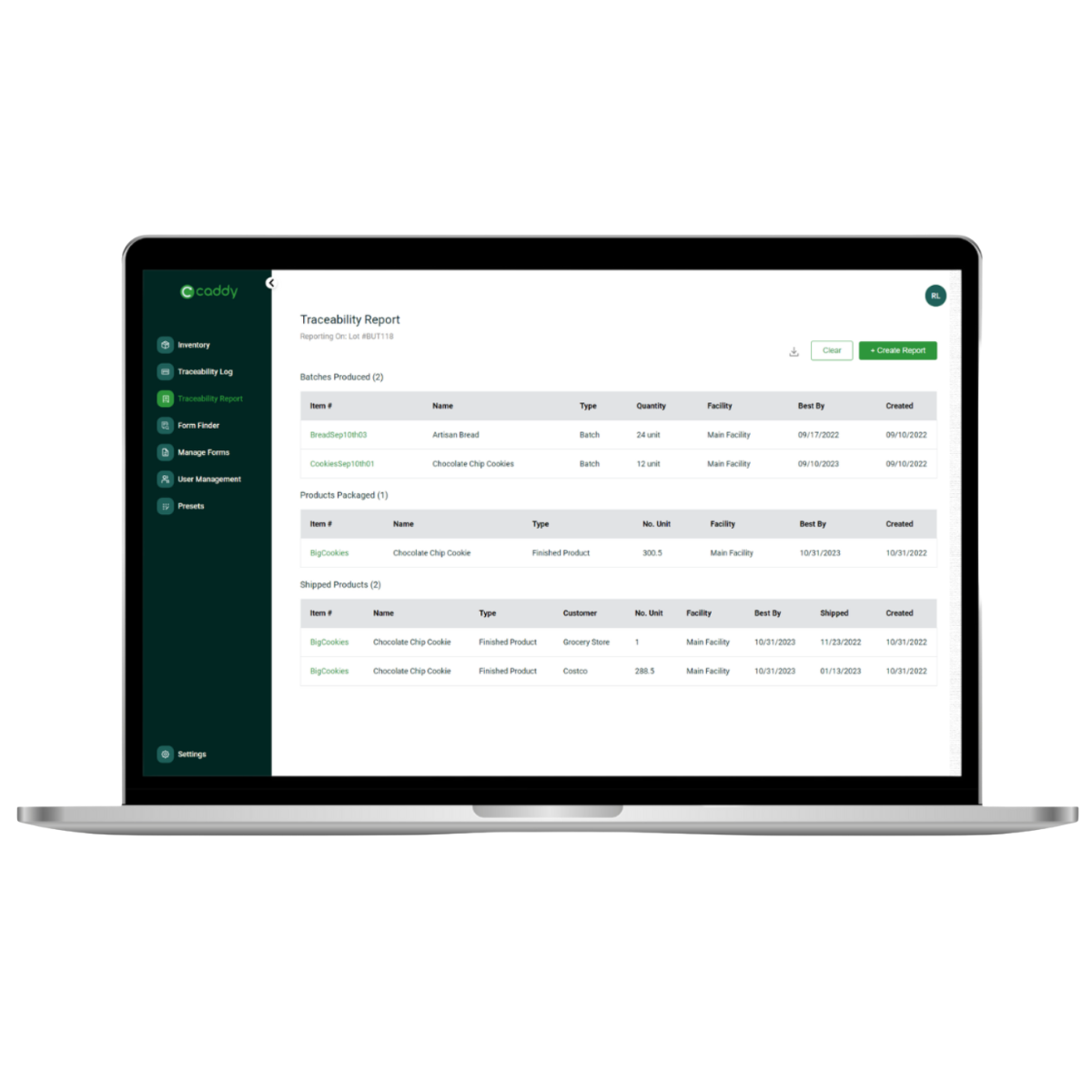

How Caddy traceability works

Caddy links your lots across receiving, production, packaging, and shipping—so you can trace in seconds.

Pick a lot as your starting point.

Choose what you’re tracing (ingredients, packaging, batches, finished goods).

Trace backward and forward in one click.

Export the report.

Attach supporting docs.

Move on.

What you can do with traceability

Run backward and forward trace reports instantly

Start from a lot code, batch, ingredient, packaging, or finished good

See where a lot came from—and where it went

Download/export reports for customers, auditors, or internal review

Attach COAs, photos, and documents to the trace trail

Reduce dependence on “who remembers where that paper or spreadsheet is”

Why traceability matters

Speed protects your brand.

When traceability is instant, you can act before a problem spreads.

You respond to audits faster.

You answer retailers with confidence.

You avoid all-hands fire drills.

.

Over manual traceability? Let’s sanity-check fit.

We’ll tell you quickly whether Caddy makes sense for your operations — and just as clearly if it doesn’t.